Membrane switches are an operating system that combines key functions, indicating elements, and instrument panels. It consists of panel, upper circuit, isolation layer, and lower circuit. It is a light-touch, normally open switch. Membrane switches have a rigorous structure, a beautiful appearance, and good sealing. They are moisture-proof and have a long service life. They are widely used in electronic communication, electronic measurement instruments, industrial control, medical equipment, automotive industry, intelligent toys, household appliances, and other fields.

The membrane switches are one of today's most popular end control switches.

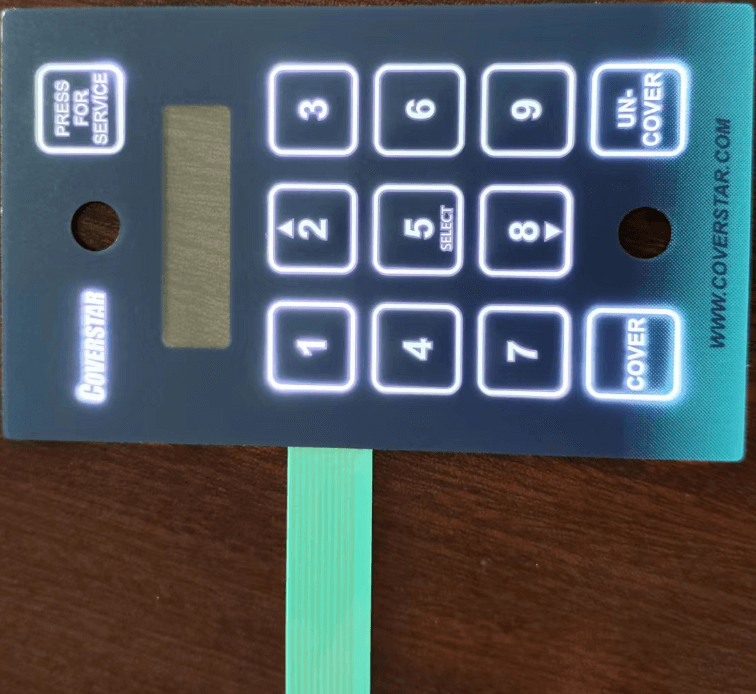

The LGF technology can be used to design membrane switches, which helps to improve the responsiveness of the membrane switch to people's needs. The LGF design membrane switch gives designers better ideas to design the controller more easily and cost-effectively. The LGF membrane switch allows for the realization of the keys' tactile feeling and backlighting at the same time through a very thin membrane switch.

The LGF technology is not just the design with LEDs on the membrane switch, but we need to solve the problem of uniform lighting diffusion over a large area with as few LEDs as possible. We also need to ensure that lighting does not diffuse to areas where it is not needed, and that there is a good tactile feeling when pressing the keys that require lighting.

We have three ways to design the LGF plate:

The first way is to design the LGF plate with translucent silicone rubber pads, which is the easiest but least effective way. With the translucent rubber pads as the LGF plate, we need to use more LEDs for the small lighting area. The silicone rubber pads need to be very thick, which will also cause the membrane switch to be very thick, and the lighting will not be very uniform. This is the very old way of designing the LGF membrane switch, and this technology is being phased out of use.

The second way is to design the LGF plate with translucent TPU. The TPU material can be made very translucent, which can help with better lighting guidance with fewer LEDs designed for a large lighting area. However, the TPU is a material that can change to a slightly yellow color after long-term use, which can affect the lighting problems. We are also phasing out the use of this technology in our products.

The third way is to design the LGF plate with the translucent PC plate, and we produce some dots which help with the lighting guide. This is a new technology that is widely used to design with the LGF membrane switch now. With this technology, it allows us to design with fewer LEDs lighting a large area and also lighting uniformly for a very thin membrane switch. The difference in dots process is also possible to cause a difference in lighting effect. The best way is to produce the dots with the tooling, as this way of designing LGF plate is very expensive due to the tooling cost, but the light guiding is the best. The other easier way is to produce the dots with silk screen printing, as this way can also catch a very good lighting guiding, and the cost is much less, and most customers agree with the LGF plate design like this. The last way is to produce the dots via laser engraving process, this process of LGF plate can also catch a very good lighting guiding, but there is also a chance of the yellow color problem with laser engraving PC plates.

Actually, if we want to design a backlighting switch, we can also use other technologies, for example: fluorescent color printing design, EL-Panel as the backlighting design, and optical fiber optics as a light guide design. We have many years of experience in designing and producing backlighting membrane switches, and we are sure we can provide you with the best way that you want.

Post time: Jul-25-2023