-

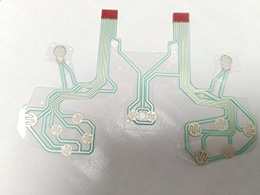

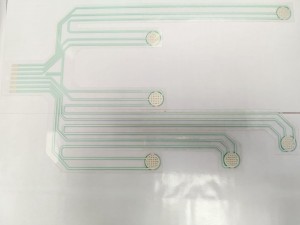

Silver printing polyester flexible circuit

Silver printing is a popular method of creating conductive traces on flexible circuits. Polyester is a commonly used substrate material for flexible circuits because of its durability and low cost. To create a silver printing polyester flexible circuit, a silver-based conductive ink is applied onto the polyester substrate using a printing process, such as screen printing or inkjet printing. The conductive ink is cured or dried to create a permanent, conductive trace. The silver printing process can be used to create simple or complex circuits, including single-layer or multi-layer circuits. The circuits can also incorporate other components, such as resistors and capacitors, to create more advanced circuitry. Silver printing polyester flexible circuits offer several benefits, including low cost, flexibility, and durability. They are commonly used in various industries, including medical devices, aerospace, automotive, and consumer electronics.

-

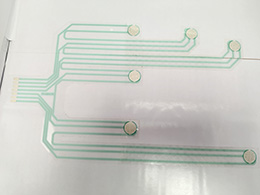

Silver chloride printing membrane circuit

A silver chloride printing membrane circuit is a type of electronic circuit that is printed on a porous membrane made of silver chloride. These circuits are typically used in bioelectronic devices, such as biosensors, that require direct contact with biological fluids. The porous nature of the membrane allows for easy diffusion of the fluid through the membrane, which in turn allows for faster and more accurate detection and sensing.

-

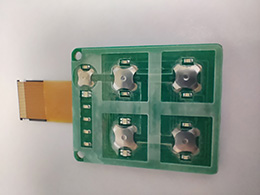

PCB combine FPC membrane circuit

PCB-based Flexible Printed Circuit (FPC) technology is an advanced circuit design methodology where a flexible circuit is printed on a thin and flexible substrate, such as plastic or polyimide film. It offers several advantages over traditional rigid PCBs, such as better flexibility and durability, greater printed circuit density, and reduced cost. PCB-based FPC technology can be combined with other circuit design methodologies like membrane circuit design to create a hybrid circuit. A membrane circuit is a type of circuit that is made using thin and flexible layers of material such as polyester or polycarbonate. It is a popular design solution for applications that require low profile and high durability. Combining PCB-based FPC technology with membrane circuit design helps designers to create complex circuits that can adapt to various shapes and forms without losing their functionality. The process involves bonding the two flexible layers together using an adhesive material, allowing the circuit to remain flexible and resilient. The combination of PCB-based FPC technology with membrane circuit design is often used in a variety of applications such as medical devices, consumer electronics, industrial equipment, and automotive components. The benefits of this hybrid circuit design methodology include improved performance, reduced size and weight, and increased flexibility and durability.

-

PCB circuits membrane switch

A PCB (Printed Circuit Board) membrane switch is a type of electronic interface that uses a thin, flexible membrane to connect and operate different circuit components. These switches are composed of multiple layers of material, including printed circuits, insulating layers, and adhesive layers, all configured to form a compact switch assembly. The basic components of a PCB membrane switch include a PCB board, a graphic overlay, and a conductive membrane layer. The PCB board serves as the base for the switch, with the graphic overlay providing a visual interface that indicates the various functions of the switch. The conductive membrane layer is applied over the PCB board and acts as the primary switch mechanism by providing a physical barrier that activates the various circuits and sends signals to the corresponding devices. The construction of a PCB membrane switch is typically very durable and long-lasting, making them ideal for use in a wide variety of applications, from consumer electronics devices to medical equipment and industrial machinery. They are also highly customizable, with the ability to create custom layouts and designs, and can be further customized with additional features like LEDs, tactile feedback, and more.

-

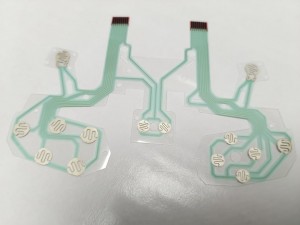

Multi-layer circuit membrane switch

A multi-layer circuit membrane switch is a type of membrane switch that is composed of several layers of materials, each with a specific purpose. It usually contains a layer of polyester or polyimide substrate that serves as the base for the switch. On top of the substrate, there are several layers that include a top printed circuit layer, an adhesive layer, a bottom FPC circuit layer, an adhesive layer, and a graphic overlay layer. The printed circuit layer contains conductive paths that are used to detect when a switch has been activated. The adhesive layer is used to bond the layers together, and the graphic overlay is the top layer that displays the switch’s labels and icons. Multi-layer circuit membrane switches are designed to be durable and reliable, making them ideal for use in a wide range of applications, including medical devices, consumer electronics, appliances, and industrial equipment. They offer benefits such as a low profile, customizable design, and ease of use, making them a popular choice for electronic devices.

-

ESD protection membrane circuit

ESD (Electrostatic Discharge) protection membranes, also known as ESD suppression membranes, are designed to protect electronic devices from electrostatic discharge, which can cause irreparable damage to sensitive electronic components. These membranes are typically used in conjunction with other ESD protection measures such as grounding, conductive flooring, and protective clothing. ESD protection membranes work by absorbing and dissipating static charges, preventing them from passing through the membrane and reaching the electronic components. They are typically made from materials that have high electrical resistance, such as polyurethane, polypropylene, or polyester, and are coated with conductive materials such as carbon to enhance their ESD suppression capabilities. One common application of ESD protection membranes is in circuit boards, where they can be used to protect against electrostatic discharge during handling, shipping, and assembly. In a typical membrane circuit, the membrane is placed between the circuit board and the component, acting as a barrier to prevent any static charges from passing through and causing damage to the circuit. Overall, ESD protection membranes are an essential component of any ESD protection plan, helping to ensure the reliable operation of electronic devices in a wide range of applications.

-

PCB circuits as the basic design membrane switch

A PCB (Printed Circuit Board) membrane switch is a type of electronic interface that uses a thin, flexible membrane to connect and operate different circuit components. These switches are composed of multiple layers of material, including printed circuits, insulating layers, and adhesive layers, all configured to form a compact switch assembly. The basic components of a PCB membrane switch include a PCB board, a graphic overlay, and a conductive membrane layer. The PCB board serves as the base for the switch, with the graphic overlay providing a visual interface that indicates the various functions of the switch. The conductive membrane layer is applied over the PCB board and acts as the primary switch mechanism by providing a physical barrier that activates the various circuits and sends signals to the corresponding devices. The construction of a PCB membrane switch is typically very durable and long-lasting, making them ideal for use in a wide variety of applications, from consumer electronics devices to medical equipment and industrial machinery. They are also highly customizable, with the ability to create custom layouts and designs, and can be further customized with additional features like LEDs, tactile feedback, and more.

-

PCB combine FPC membrane circuit

PCB-based Flexible Printed Circuit (FPC) technology is an advanced circuit design methodology where a flexible circuit is printed on a thin and flexible substrate, such as plastic or polyimide film. It offers several advantages over traditional rigid PCBs, such as better flexibility and durability, greater printed circuit density, and reduced cost. PCB-based FPC technology can be combined with other circuit design methodologies like membrane circuit design to create a hybrid circuit. A membrane circuit is a type of circuit that is made using thin and flexible layers of material such as polyester or polycarbonate. It is a popular design solution for applications that require low profile and high durability. Combining PCB-based FPC technology with membrane circuit design helps designers to create complex circuits that can adapt to various shapes and forms without losing their functionality. The process involves bonding the two flexible layers together using an adhesive material, allowing the circuit to remain flexible and resilient. The combination of PCB-based FPC technology with membrane circuit design is often used in a variety of applications such as medical devices, consumer electronics, industrial equipment, and automotive components. The benefits of this hybrid circuit design methodology include improved performance, reduced size and weight, and increased flexibility and durability.

-

ESD protection membrane circuit

ESD (Electrostatic Discharge) protection membranes, also known as ESD suppression membranes, are designed to protect electronic devices from electrostatic discharge, which can cause irreparable damage to sensitive electronic components. These membranes are typically used in conjunction with other ESD protection measures such as grounding, conductive flooring, and protective clothing. ESD protection membranes work by absorbing and dissipating static charges, preventing them from passing through the membrane and reaching the electronic components.

-

Multi-layer circuit membrane switch

A multi-layer circuit membrane switch is a type of membrane switch that is composed of several layers of materials, each with a specific purpose. It usually contains a layer of polyester or polyimide substrate that serves as the base for the switch. On top of the substrate, there are several layers that include a top printed circuit layer, an adhesive layer, a bottom FPC circuit layer, an adhesive layer, and a graphic overlay layer. The printed circuit layer contains conductive paths that are used to detect when a switch has been activated. The adhesive layer is used to bond the layers together, and the graphic overlay is the top layer that displays the switch’s labels and icons. Multi-layer circuit membrane switches are designed to be durable and reliable, making them ideal for use in a wide range of applications, including medical devices, consumer electronics, appliances, and industrial equipment. They offer benefits such as a low profile, customizable design, and ease of use, making them a popular choice for electronic devices.

-

Silver printing polyester flexible circuit

Silver printing is a popular method of creating conductive traces on flexible circuits. Polyester is a commonly used substrate material for flexible circuits because of its durability and low cost. To create a silver printing polyester flexible circuit, a silver-based conductive ink is applied onto the polyester substrate using a printing process, such as screen printing or inkjet printing. The conductive ink is cured or dried to create a permanent, conductive trace. The silver printing process can be used to create simple or complex circuits, including single-layer or multi-layer circuits. The circuits can also incorporate other components, such as resistors and capacitors, to create more advanced circuitry. Silver printing polyester flexible circuits offer several benefits, including low cost, flexibility, and durability. They are commonly used in various industries, including medical devices, aerospace, automotive, and consumer electronics.

-

Silver chloride printing membrane circuit

A silver chloride printing membrane circuit is a type of electronic circuit that is printed on a porous membrane made of silver chloride. These circuits are typically used in bioelectronic devices, such as biosensors, that require direct contact with biological fluids. The porous nature of the membrane allows for easy diffusion of the fluid through the membrane, which in turn allows for faster and more accurate detection and sensing.